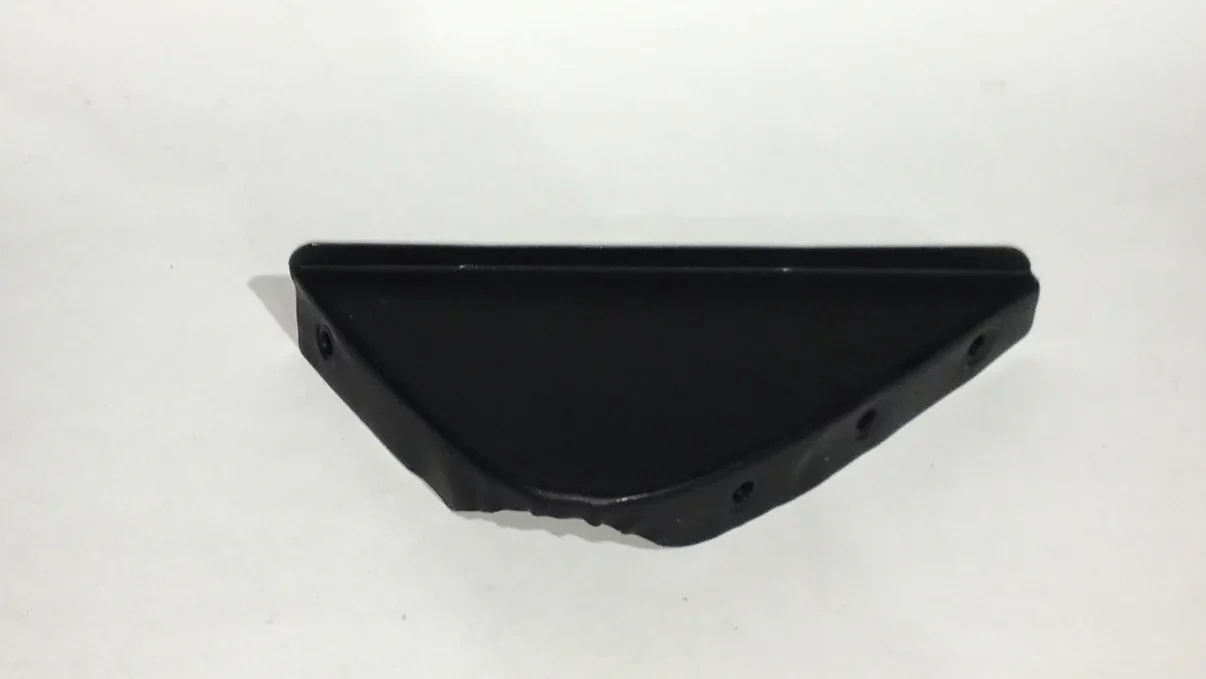

Bugeye rear bumpers aren’t so much bumpers as they are decorative chrome for the rear of the car, but nevertheless they serve as a very important buffer between the rear sheet metal of the car and the general driving public. While uncomplicated, there is still a right and wrong way to install rear bumpers on your Sprite. In the video below, I explain how to fit rear Sprite overriders for accurate alignment and maximum protection!

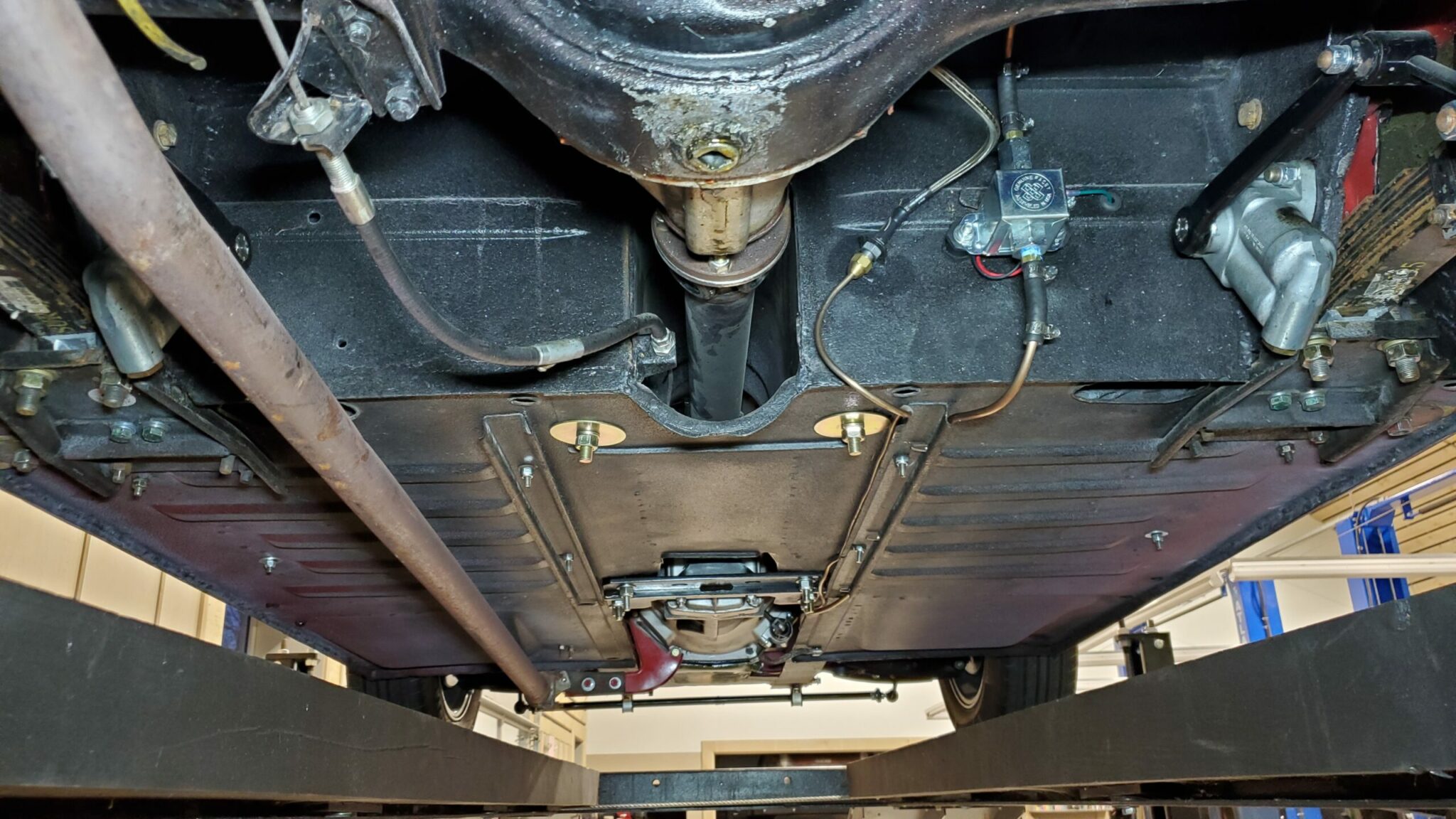

In addition to proper alignment, having the bumpers installed incorrectly can cause an interference issue with the exhaust, discoloring the chrome and ruining an otherwise perfectly nice overrider.

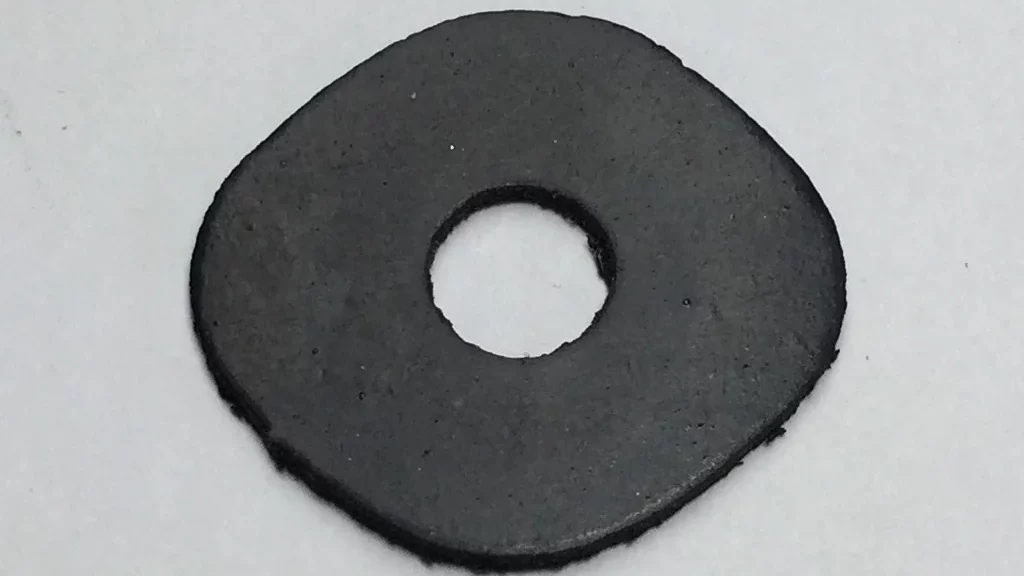

Should you need to replace or upgrade your Bugeye’s rear overriders, we offer a full line of parts to do so! Click the photos below to learn more or click here for our complete catalog!